Blogs

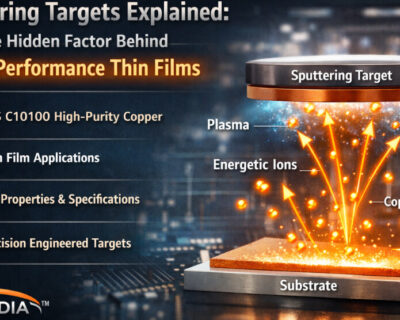

Sputtering Target Lifecycle: 5 Performance Truths That Redefine Planar vs Rotatable Targets | DOMADIA™

Sputtering Target Lifecycle Is Where Hidden Costs Begin

A semiconductor fab once tracked its sputtering process downtime for six months.

The issue wasn’t plasma instability.

It wasn’t chamber contamination.

It wasn’t operator error.

The root cause turned out to be far more expensive: frequent planar target changeovers.

This is where the debate between planar vs rotatable sputtering targets stops being technical and starts becoming financial. When viewed through the lens of sputtering target lifecycle, the performance differences directly impact uptime, yield consistency, labor cost, and scrap rates.

DOMADIA™ works closely with thin-film manufacturers who have learned one hard truth: purchase price is irrelevant if lifecycle cost is ignored.

What Are Planar and Rotatable Sputtering Targets?

Before diving into lifecycle truths, let’s establish clarity.

Planar Sputtering Targets

Flat targets bonded to a backing plate, widely used in legacy PVD systems. Material utilization is limited to the erosion groove formed during sputtering.

Rotatable Sputtering Targets

Cylindrical targets that rotate continuously during deposition, exposing fresh surface area and enabling uniform erosion across nearly the entire target volume.

On paper, both achieve deposition.

In practice, their sputtering target lifecycle behavior differs drastically.

Truth #1: Material Utilization Drives Lifecycle Economics

Planar Targets

- Typical material utilization: 25–40%

- Large portion of usable material remains unused

- Frequent target replacement despite remaining metal

Rotatable Targets

- Material utilization: 80–90%

- Uniform erosion maximizes usable material

- Fewer replacements per production cycle

Lifecycle Impact:

Higher utilization directly lowers cost-per-wafer. In sputtering target lifecycle analysis, rotatable targets consistently outperform planar designs by reducing scrap metal and procurement frequency.

Truth #2: Downtime Is the Silent Cost Multiplier

Each planar target replacement involves:

- Chamber venting

- Cooling cycles

- Bonded target removal

- Requalification runs

Rotatable targets, by contrast:

- Run longer between changes

- Reduce vent cycles

- Stabilize process windows

Lifecycle Impact:

In high-throughput fabs, downtime costs often exceed material costs. A longer sputtering target lifecycle translates directly into higher tool availability and improved ROI.

Truth #3: Film Uniformity Affects Yield More Than Specs

Planar targets develop deep erosion grooves over time. As erosion progresses:

- Plasma distribution shifts

- Deposition rates fluctuate

- Film thickness uniformity degrades

Rotatable targets maintain:

- Stable erosion geometry

- Consistent deposition rates

- Better film uniformity across long runs

Lifecycle Impact:

Yield loss compounds silently. When evaluated over the full sputtering target lifecycle, rotatable targets significantly reduce rework and wafer scrap.

Truth #4: Thermal Stress Shortens Planar Target Life

Planar targets experience localized thermal loading due to static erosion zones. This leads to:

- Higher risk of cracking

- Bond layer degradation

- Target debonding failures

Rotatable targets distribute thermal load evenly through rotation, reducing mechanical stress.

Lifecycle Impact:

Lower failure risk improves predictability. In sputtering target lifecycle planning, predictability is often more valuable than raw deposition speed.

Truth #5: Environmental Cost Is Now a Business Cost

Every discarded planar target:

- Requires energy-intensive recycling

- Generates logistics emissions

- Consumes fresh raw material sooner

Rotatable targets last longer, meaning:

- Fewer scrap cycles

- Reduced recycling frequency

- Lower environmental footprint

DOMADIA™ Perspective:

Longer sputtering target lifecycle is not just economical—it’s environmentally responsible. Less recycling equals lower total environmental impact over time.

Planar vs Rotatable: Lifecycle Cost Comparison

| Factor | Planar Targets | Rotatable Targets |

| Material Utilization | Low | Very High |

| Replacement Frequency | High | Low |

| Downtime Cost | High | Reduced |

| Yield Stability | Variable | Consistent |

| Environmental Impact | Higher | Lower |

Despite a higher initial price, rotatable targets win decisively when sputtering target lifecycle cost is considered.

Mindset Shift: Stop Buying Targets. Start Buying Lifecycle Performance.

Many procurement teams focus on unit price.

High-performing fabs focus on cost per deposited micron over time.

This mindset shift is why advanced manufacturers increasingly migrate toward rotatable sputtering targets—even in systems originally designed around planar geometries.

DOMADIA™ supports this transition by supplying precision-engineered sputtering targets designed for long lifecycle stability, not just short-term savings.

Actionable Takeaway

If your facility tracks:

- Downtime losses

- Yield drift

- Scrap metal volume

- Maintenance labor hours

You already have the data needed to evaluate true sputtering target lifecycle cost.

Ignoring it is expensive.

Why DOMADIA™

DOMADIA™ provides both planar and rotatable sputtering targets with a focus on:

- High-density metallurgy

- Uniform grain structure

- Controlled bonding integrity

- Lifecycle-driven performance selection

The goal isn’t to sell a target.

The goal is to optimize sputtering target lifecycle economics.

Conclusion

Planar sputtering targets still have their place—but when uptime, yield stability, and environmental responsibility matter, rotatable targets deliver superior lifecycle value.

When viewed through the lens of sputtering target lifecycle, the decision becomes less about price and more about performance that compounds over time.

That’s where smart fabs win.

Optimize Your Sputtering Target Lifecycle Performance

DOMADIA™ helps you select planar or rotatable sputtering targets engineered for consistent deposition and extended lifecycle value.

Improve uptime, deposition consistency, and lifecycle cost efficiency — Contact Us to get expert guidance on selecting the right planar or rotatable sputtering target for your process.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#HighTemperatureSilicaYarns #RTDCableInsulation #HighTemperatureInsulation #SilicaYarn #ThermalProtection #IndustrialSensors #FurnaceInstrumentation #ProcessAutomation #ExtremeHeat #DOMADIA

Directly whatsapp us for an Enquiry: https://wa.link/kairav

We’ve supplied to Mumbai, Pune, Indore, Jaipur, and Surat—serving industries across Maharashtra, Madhya Pradesh, Rajasthan, Gujarat, and Goa, with exports to Germany, USA, Japan, South Korea, and Italy.