Blogs

The Lifecycle of Electrical Insulation Materials — From Yarn to Paper to Power | DOMADIA™

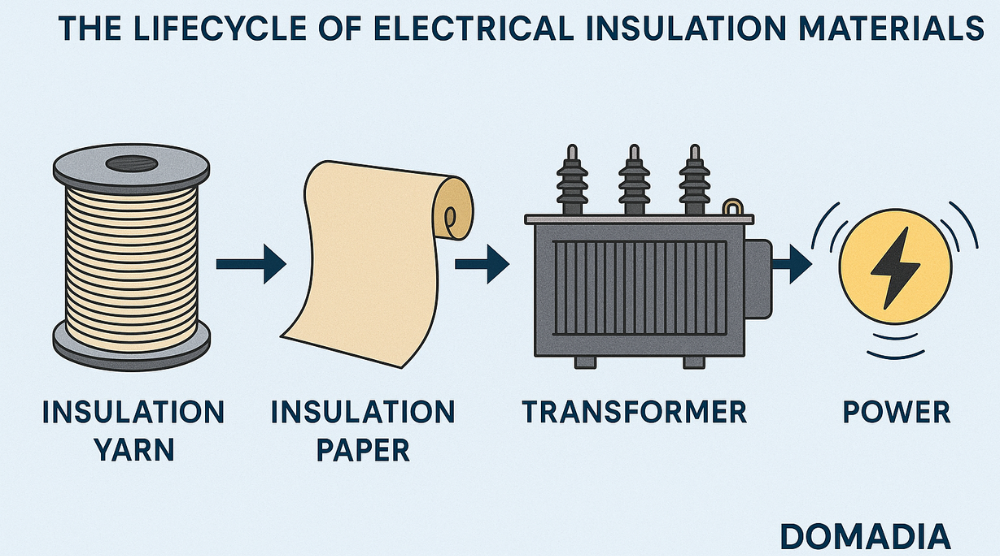

Introduction: From Fiber to Power

Every megawatt of electricity that powers our homes and industries passes through layers of protection—not just wires and cables, but insulation materials that silently ensure safety, reliability, and efficiency.

At DOMADIA™, we trace this journey from the very first filament of insulating yarn to high-performance paper that keeps transformers, motors, and cables alive and sparking with energy.

Let’s explore the fascinating lifecycle of electrical insulation materials — a process that transforms soft threads into the strong backbone of modern power systems.

Stage 1: The Beginning — Insulation Yarns

Electrical insulation starts with specialized yarns. These are not ordinary textile fibers but engineered materials made from glass, polyester, polyimide, or aramid.

Key Properties of Insulation Yarns:

- High dielectric strength

- Heat resistance up to 400°C (for polyimide and glass yarns)

- Non-flammable and chemically stable

- Superior tensile and mechanical strength

Popular Insulation Yarns by DOMADIA™:

- Fiberglass Yarn: Ideal for high-voltage applications

- Polyimide Yarn: Exceptional for aerospace and high-temperature environments

- Polyester Yarn: Common in general-purpose insulation

These yarns are braided, woven, or coated to form the base for tapes, sleeving, and composite materials used in motor windings, transformers, and coils.

Stage 2: Transformation — Insulation Papers

Once the yarns and fibers are processed, they are converted into insulation papers, forming the next critical layer in the electrical lifecycle.

Types of Insulation Papers:

- Crepe Paper: Flexible and stretchable; perfect for transformer winding insulation.

- Kraft Paper: Dense and durable; used in cable wrapping and oil-filled transformers.

- Aramid Paper: Heat-resistant; found in aerospace electrical systems.

Key Characteristics:

- Excellent dielectric properties

- Oil-absorption capability for cooling

- High tear and tensile strength

- Resistant to aging and thermal degradation

These papers act as dielectric barriers — the shield that prevents short circuits and ensures long equipment life.

Stage 3: Integration — The Power Assembly

Once yarns and papers are ready, they are assembled into functional components — cables, coils, insulation tapes, and transformer layers.

Applications:

- Transformers: Layer insulation with crepe and kraft papers

- Motors: Coil insulation using fiberglass or aramid yarn

- Cables: Wrapping with multi-layer insulation tapes

- Generators: High-voltage insulation for coils and terminals

DOMADIA™ ensures each insulation component meets international standards like IEC 60554, ASTM D202, and IS 7404, guaranteeing safety and durability across voltage classes.

Stage 4: Sustainability — Recycling and Reuse

Electrical insulation materials are built to last, but sustainability is now an equal priority. DOMADIA™ emphasizes eco-friendly production and recyclable composites.

Sustainability Highlights:

- Reduced polymer waste by using recyclable glass and aramid fibers.

- Extended material lifespan reduces the need for frequent replacements.

- Lower carbon footprint through optimized energy processes.

The longer insulation lasts, the less frequent the recycling, meaning lower environmental impact — a small but vital step toward greener energy infrastructure.

Stage 5: The Power Connection — End of the Cycle

Finally, these materials perform their duty — carrying power safely across industries and cities. From small motors to mega transformers, the reliability of electricity depends on the silent efficiency of these insulation materials.

DOMADIA™ insulation solutions have powered countless systems in automotive, aerospace, electrical, and renewable sectors, ensuring performance under every condition — from scorching heat to freezing cold.

Conclusion: From Yarn to Power — The DOMADIA™ Legacy

The lifecycle of electrical insulation materials is more than an industrial process — it’s a story of transformation, innovation, and reliability.

From insulation yarn to paper and finally to power, each stage defines how the world stays connected — safely and efficiently.

At DOMADIA™, we’re proud to contribute to this journey — one fiber, one paper, and one spark at a time.

Empower Your Projects with Reliable Insulation Solutions.

Choose DOMADIA™ — where innovation meets insulation.

Explore Our Insulation Materials: domadia.net

Follow us on LinkedIn: https://www.linkedin.com/in/kairav

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#DOMADIA #ElectricalInsulation #InsulationPaper #InsulationYarn #PowerEngineering #TransformerTechnology #SustainableMaterials #IndustrialInnovation #EnergyEfficiency #SmartManufacturing

Directly whatsapp us for an Enquiry: https://wa.link/kairav