Thermocouple Cables

DOMADIA™ Thermocouple Cables

Precision Temperature Sensing with Reliable Thermocouple Cables

Thermocouple cables are critical components used for accurate and reliable temperature measurement across various industries. These specialized cables are essential for manufacturing thermocouple probes that detect temperature at the point of Cold Junction Compensation (CJC). Whether you’re working in a heavy industrial environment or a controlled laboratory setting, thermocouple cables provide the durability and precision needed for optimal performance.

What Are Thermocouple Cables?

Thermocouple cables consist of paired conductors made from dissimilar metals. These conductors generate a thermoelectric current when connected at a junction and exposed to temperature. Each conductor serves a specific function — one is positively charged and the other negatively charged — to enable accurate thermal readings.

Extension-grade thermocouple wire is designed to carry the signal from the sensor to the measuring device without being directly exposed to high temperatures. These cables often come with robust insulation and shielding for stability in demanding environments.

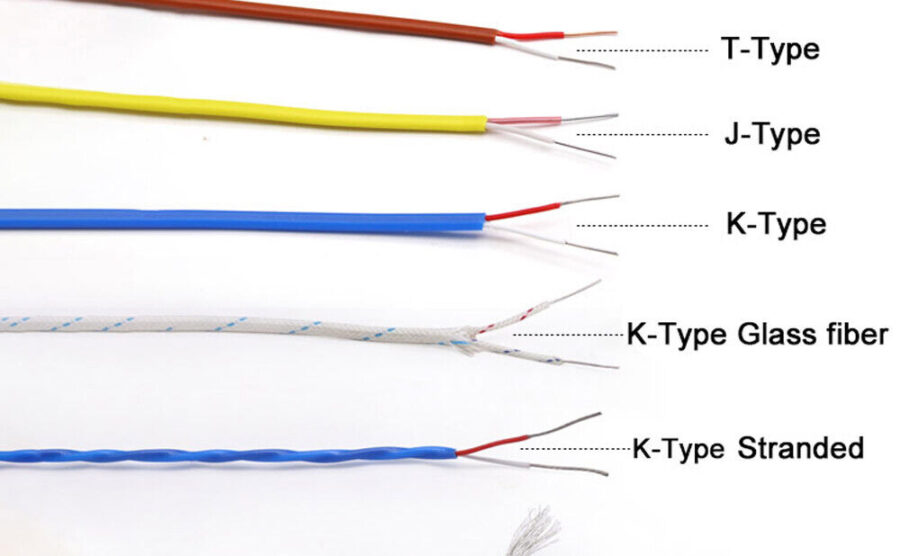

Types of Thermocouple Cables

Different applications require different thermocouple types based on the temperature range and metal composition. Below are some commonly used thermocouples cable types:

Standard Types

Type J:

Suitable for general-purpose use, with a temperature range of -40°C to 760°C. It consists of iron and constantan (copper-nickel alloy).

Type K:

A widely used general-purpose thermocouple, with a temperature range of -270°C to 1372°C. It’s made of chromel (nickel-chromium alloy) and alumel (nickel-aluminum-manganese-silicon alloy).

Type T:

Ideal for low-temperature applications, with a temperature range of -250°C to 350°C. It consists of copper and constantan.

Type E:

Known for its high output and is suitable for a temperature range of -200°C to 900°C. It’s made of chromel and constantan.

Type N:

Similar in accuracy and temperature range to Type K, but with enhanced stability, with a temperature range of -270°C to 1260°C. It’s made of Nicrosil and Nisil alloys.

Type R, Type S, and Type B:

Noble metal thermocouples used for high-temperature applications, with Type R consisting of platinum-rhodium and platinum, and Type S and B also using platinum-rhodium and platinum alloys.

Extension Grades (denoted with ‘X’ suffix)

EX, JX, KX, TX, BX, SX

These extension cables are used to connect the thermocouple probe to controllers, recorders, or display devices.

Factors to Consider When Choosing a Thermocouple:

Temperature Range:

Select a thermocouple type that can accurately measure the temperature range of your application.

Environmental Conditions:

Consider the chemical resistance and resistance to abrasion or vibration in the environment where the thermocouple will be used.

Accuracy Requirements:

Different thermocouple types have varying degrees of accuracy, so choose one that meets your needs.

Thermocouple Wire Configurations:

Bare Thermocouple Wire: Wire without any insulation, suitable for specific applications.

Duplex Insulated Thermocouple Wire: The most common type, with two insulated wires within a single sheath.

Metal Sheathed Thermocouple Wire: Wire encased in a metal sheath for added protection and ruggedness.

Key Thermocouple Cable Constructions

Choosing the right thermocouple cable construction is essential for ensuring accurate performance, durability, and safety in your application. Here are the most common configurations and materials used:

🔹 Type K – Chromel/Alumel

- Most Popular Type: Widely used across industrial and laboratory applications.

- Composition:

- Positive Conductor: Chromel (Nickel-Chromium – NiCr)

- Negative Conductor: Alumel (Nickel-Aluminum – NiAl)

- Temperature Range: Suitable for general-purpose measurements up to ~1260°C.

🔸 EX / TX Variants

- Enhanced Shielding Options:

- EX: Nickel-Chromium / Copper-Nickel (NiCr / CuNi)

- TX: Copper / Copper-Nickel (Cu / CuNi)

- Screening & Armoring:

- Available with individual screening, collective screening, or double steel tape armor.

- Key Feature: Excellent protection against electromagnetic interference (EMI) in electrically noisy environments.

Insulation Material Options

Different insulation types are used to withstand various temperature levels, chemical exposures, and mechanical stresses:

| Material | Properties | Applications |

| PVC | Flexible, economical | Indoor, dry environments |

| Teflon (PTFE/FEP) | High chemical resistance, up to 250°C | Chemical plants, harsh industrial zones |

| Fiberglass | Heat-resistant up to 500°C | Ovens, kilns, and metal treatment |

| Ceramic | Extreme temperature tolerance | Furnaces, aerospace, metallurgy |

Applications of Thermocouple Cables

Thermocouple cables are indispensable for industries that demand precision, durability, and real-time thermal monitoring. From industrial furnaces to food processing lines and medical equipment, these cables help keep operations running smoothly and safely.

Industrial & Manufacturing

- Process Optimization:

Ensure peak efficiency and safety in manufacturing plants, chemical refineries, and smelters by monitoring temperatures in real-time. - Furnace & Kiln Control:

Vital for temperature regulation in furnaces, kilns, and reactors used for heat treatment, metal forging, and ceramics production. - Extrusion Machinery:

Monitor molten plastic temperatures under high pressure, enhancing product consistency in plastics and rubber manufacturing. - Power Generation:

Maintain safe and efficient operations in boilers, turbines, and control systems in thermal and nuclear power plants.

HVAC & Building Automation

- HVAC Systems:

Achieve energy efficiency and comfort by monitoring temperatures in heating, ventilation, and air conditioning systems. - Smart Thermostats:

Used in residential and commercial thermostats for precise climate control and temperature management.

Food & Beverage Industry

- Cooking & Chilling Precision:

Safeguard food quality and meet safety standards during baking, boiling, freezing, and chilling processes. - Food Chain Monitoring:

From farm to fork, track temperatures across the supply chain to ensure freshness and reduce spoilage. - Specialized Equipment:

Used in ovens, hotplates, fryers, pasteurizers, and steam kettles to maintain optimal cooking conditions.

Automotive & Aerospace

- Automotive Diagnostics:

Monitor critical zones such as engine blocks, exhaust manifolds, and cabin climate systems to improve performance and emissions control. - Aerospace Engineering:

Designed to survive rapid thermal changes and high-stress conditions in aircraft, spacecraft, and ground support systems.

Medical & Laboratory

- Medical Equipment:

Used in thermometers, incubators, and sterilization systems where precision and reliability are essential for patient care. - Scientific Research:

A cornerstone for temperature-sensitive experiments in R&D labs, physics research, and materials testing.

Safety & Home Appliances

- Flame Sensors:

Built into gas-powered devices like water heaters, stoves, and boilers to detect flames and ensure safe operation. - Fire Detection Systems:

Integrated into alarm systems for continuous heat detection in critical infrastructure and industrial facilities.

How to Choose the Right Thermocouple Cable

✅ Determine the Thermocouple Type

Match the cable type (K, J, T, E, etc.) to your required temperature range and environment.

✅ Evaluate Temperature Range

Ensure the cable can withstand the operational temperatures and signal accuracy requirements.

✅ Check Environmental Resistance

Assess exposure to moisture, chemicals, or mechanical stress, and choose appropriate insulation.

✅ Choose Proper Insulation

PVC for general use, Teflon for chemical resistance, Fiberglass for high temperatures, Ceramic for extreme heat / Asbestos free Silica Yarn.

✅ Ensure Compatibility and Scalability

Confirm that the cable fits existing systems and can accommodate future upgrades.

Installation & Maintenance Best Practices

- Plan Layouts: Strategically position cables to avoid heat and EMI interference.

- Handle Gently: Avoid sharp bends and stress on junctions.

- Proper Grounding: Eliminate noise interference for clean signal transmission.

- Regular Calibration: Maintain system accuracy with scheduled calibration.

- Routine Inspection: Check for wear, cracks, or discoloration.

- Keep Clean: Remove contaminants that may affect performance.

Why Choose DOMADIA™ Thermocouple Cables?

With decades of expertise in temperature sensing and specialty alloy solutions, DOMADIA™ stands at the forefront of thermocouple cable innovation and reliability. Engineered for precision and performance, our thermocouple cables are trusted by industries worldwide to deliver exceptional accuracy and durability, even in the harshest environments.

Here’s why DOMADIA™ is the preferred choice:

✅ Unmatched Accuracy

Our cables are crafted to ensure precise temperature measurement, critical for quality control and safety in industrial processes.

✅ Built to Last

With rugged construction and high-quality materials, DOMADIA™ thermocouple cables withstand extreme temperatures, mechanical stress, and corrosive environments.

✅ Advanced Insulation & Shielding

Choose from a wide range of insulation types and shielding configurations to match your application — including options for EMI protection, high-temperature endurance, and environmental resistance.

✅ Expert Support

Our dedicated team offers personalized consultation, technical assistance, and after-sales support to help you select and maintain the ideal cable solution.

Frequently Asked Questions (FAQs)

How long do thermocouple wires last?

Thermocouple lifespan varies with type, temperature, and environment. Under typical conditions, they can last several years. In harsher settings, expect a shorter life due to stress and exposure.

What is the temperature range of thermocouple cables?

Thermocouples can measure from -200°C to +1800°C, depending on the type. Performance may vary based on alloy composition and calibration.

Related Products

1. Copper Conductor Cables

2. Nickel Conductor Cables

3. Beryllium Copper Conductor Cables

Error: Contact form not found.