Hastelloy C22 Wire Mesh

High-Performance Alloy C22 Woven, Hexagonal & Welding Wiremesh | Domadia™

Introduction

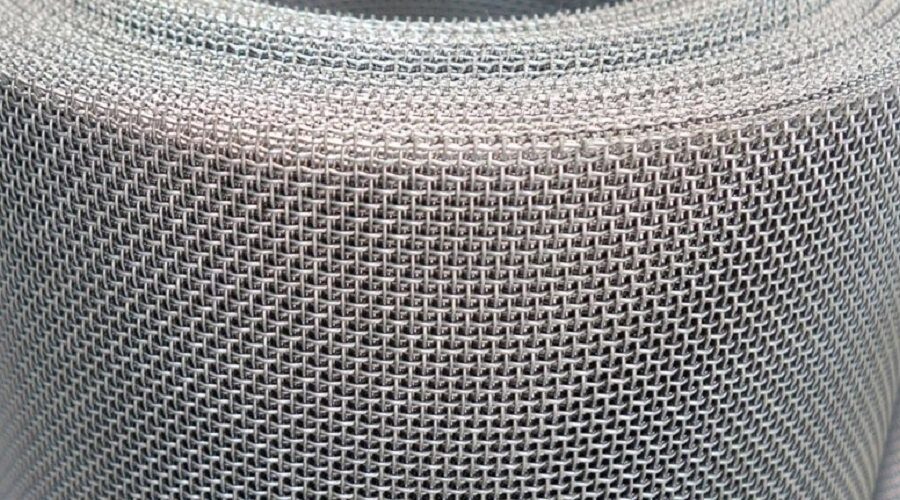

Hastelloy C22 Wire Mesh is a premium-grade nickel-chromium-molybdenum alloy mesh known for its outstanding corrosion resistance and exceptional mechanical strength. Designed for the world’s most demanding chemical, marine, and high-temperature applications, Alloy C22 wire mesh offers reliability, safety, and long-lasting durability. At Domadia™, we supply precision-engineered Hastelloy C22 woven, welding, hexagonal, netting, spring steel, and fencing wire mesh that meet global quality standards.

Wire mesh — also known as wire net, wire Jaali, wire strainer, wire grid, wire grill, and micronet — is a versatile metal screening material used across industrial, commercial, and architectural applications. Manufactured by weaving or welding high-quality metal wires, wire mesh provides excellent strength, durability, and precise opening sizes for filtration, separation, protection, ventilation, reinforcement, and screening.

Available in multiple materials (stainless steel, galvanized steel, mild steel, and more) and a wide range of mesh sizes, wire mesh is widely used in construction, agriculture, mining, chemical processing, food industry equipment, and household applications. Its combination of corrosion resistance, long service life, and customizable specifications makes it one of the most reliable and cost-effective metal mesh solutions on the market.

About the Product

DOMADIA™ Hastelloy C22 Wire Mesh is manufactured using high-purity Alloy C22 (UNS N06022 / WNR 2.4602) as per ASTM B574 / ASME SB574 standards. This alloy offers exceptional resistance to pitting, crevice corrosion, stress corrosion cracking, and aggressive chemical environments—including chlorides, acids, and seawater.

With thermal stability up to 1300°F (700°C), excellent weldability, and superior tensile strength, Alloy C22 wire mesh is ideal for critical filtration, separation, screening, and high-temperature structural applications.

Hastelloy C22 Wire Mesh – Chemical Composition

| Element | Percentage (%) |

| Nickel (Ni) | Balance (≈ 50.015% min) |

| Chromium (Cr) | 20.00 – 22.50% |

| Molybdenum (Mo) | 12.50 – 14.50% |

| Iron (Fe) | 2.00 – 6.00% |

| Cobalt (Co) | 2.50% max |

| Carbon (C) | 0.010% max |

| Manganese (Mn) | 0.50% max |

| Silicon (Si) | 0.08% max |

| Sulfur (S) | 0.02% max |

| Phosphorus (P) | 0.02% max |

Key Features & Advantages

- Superior Corrosion Resistance against hydrochloric, sulfuric acid, chlorides, hypochlorites & other harsh chemicals

- High-Temperature Stability up to 1300°F (700°C)

- Exceptional Mechanical Strength with long-term durability

- Non-magnetic and thermally stable, ideal for precision applications

- Excellent weldability without sensitization

- Smooth, durable surface resistant to fraying and mechanical damage

- Available in multiple weave patterns & custom sizes for industry-specific needs

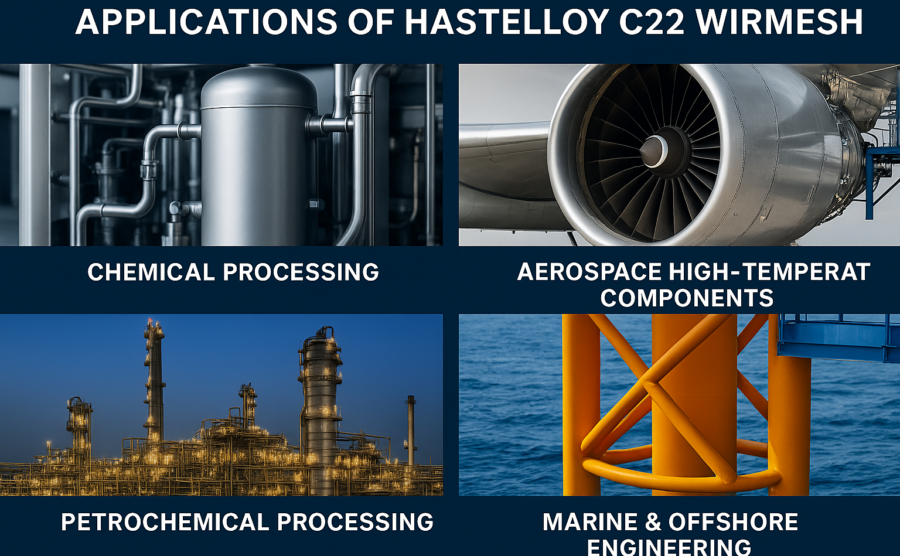

Applications of Hastelloy C22 Wire Mesh

- Chemical Processing Plants: Used in filters, reactors, dryers, and heat exchangers exposed to aggressive chemical media.

- Aerospace & Gas Turbines: Ideal for vanes, blades, afterburners, and components requiring high strength at elevated temperatures.

- Marine & Offshore Engineering: Highly resistant to saltwater, chlorides, and seawater corrosion.

- Pharmaceutical & Food Processing: Ensures contamination-free filtration due to chemical cleanliness.

- Petrochemical & Gas Processing: Used in catalyst recovery, hydrocarbon processing, and sour-gas facilities.

- Wastewater & Pollution Control: Perfect for fine filtration and protective screens preventing particulate entry.

Why Choose Domadia™

- Leading supplier of Hastelloy C22 wire mesh with unmatched material quality

- Products manufactured to ASTM / ASME international standards

- 100% certified materials with test reports, and PMI verification

- High precision weaving, uniform aperture size, and excellent build quality

- Custom mesh sizes, aperture options, and weave patterns available

- Strong global network for timely deliveries across India & worldwide

Connect With Us

Find the perfect corrosion-resistant wire mesh for your application with Domadia™. Whether you work in chemical processing, marine systems, high-temperature manufacturing, or filtration technology, our experts are here to support you with high-quality Alloy C22 Wire Mesh solutions. Let us help you choose the right mesh to enhance performance, durability, and safety across your operations.

Ready to Buy?

For pricing, bulk orders, and technical assistance:

Related Products

- Hastelloy C276 Wire Mesh

- Inconel 625 Wire Mesh

- Monel 400 Wire Mesh

- Titanium Grade 2 Wire Mesh

- Nickel 200 Wire Mesh

Frequently Asked Questions

1. What makes Hastelloy C22 Wire Mesh ideal for corrosion-intensive applications?

Its Ni-Cr-Mo alloy composition provides unmatched resistance to acids, chlorides, and oxidizing and reducing agents.

2. Is Alloy C22 safe for high-temperature applications?

Yes, it maintains structural integrity and oxidation resistance up to 1300°F (700°C).

3. Do you offer customized mesh sizes and weaves?

Absolutely—Domadia™ offers plain, twill, Dutch weave, and custom designs.

4. Can Hastelloy C22 Wire Mesh be welded?

Yes, it offers excellent weldability without the risk of sensitization.

5. Does the product come with test certificates?

Yes, we provide EN 10204/3.1, Radiography Reports, PMI Tests, and more.

6. What industries commonly use this mesh?

Chemical processing, petrochemicals, aerospace, marine, pharmaceuticals, and wastewater systems.

7. Is the mesh resistant to seawater?

Yes, it performs exceptionally well in chloride-rich marine environments.

8. Do you offer export packaging?

Yes, all products are securely packed in wooden cases for international shipping.

Error: Contact form not found.