COPPER NICKEL FOILS

DOMADIA™ Copper Nickel Foils

Precision. Reliability. Performance.

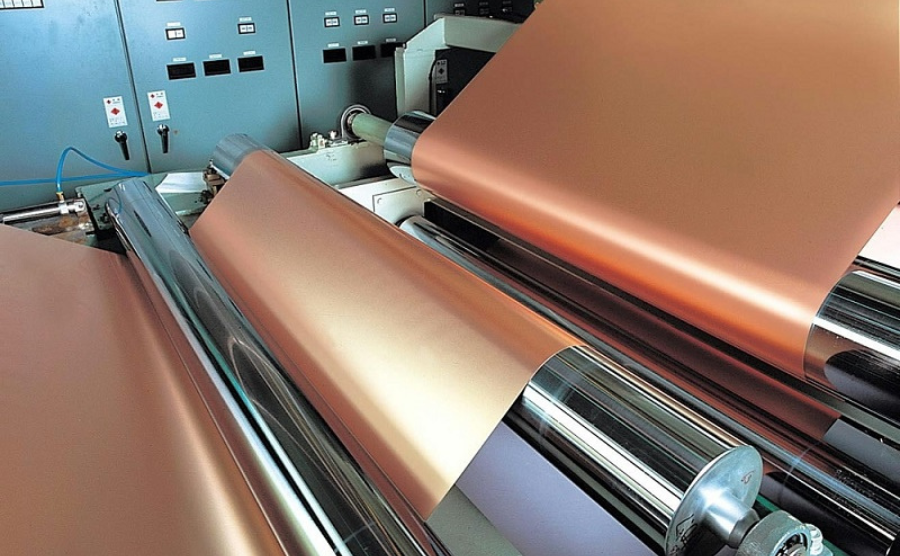

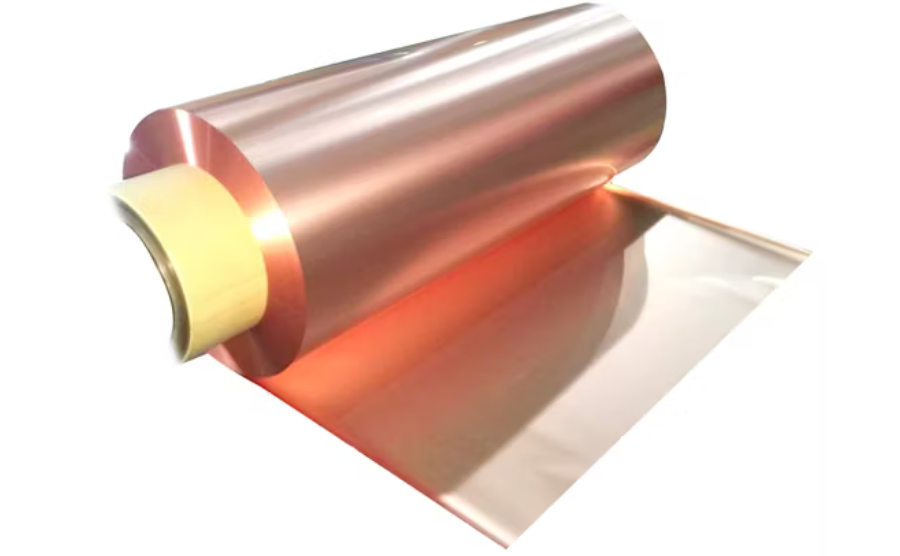

Welcome to DOMADIA™, your trusted source for Copper Nickel Foils engineered for superior corrosion resistance, thermal stability, and marine-grade durability. Our foils are designed to meet the rigorous standards of critical industries such as marine, electronics, aerospace, and instrumentation.

Types of DOMADIA™ Copper Nickel Foils

DOMADIA™ offers a versatile range of Copper Nickel (CuNi) Foils, categorized by alloy composition and tailored for specific environments and technical demands. Below are the major types:

1. CuNi90/10 Foil (UNS C70600 / DIN 2.0872)

- Composition: ~90% Copper, 10% Nickel

- Characteristics:

- Excellent resistance to sea water and brine

- High ductility and toughness

- Superior weldability

- Applications: Marine cooling systems, condenser tubes, offshore piping

2. CuNi70/30 Foil (UNS C71500 / DIN 2.0882)

- Composition: ~70% Copper, 30% Nickel

- Characteristics:

- Higher strength and corrosion resistance than 90/10

- Better performance under elevated temperatures

- Superior biofouling resistance

- Applications: Heat exchangers, desalination plants, naval ship systems

3. CuNi30Mn1FeTi Foil (DOMADIA™ Specialty Alloy)

- Composition: Copper-Nickel alloy with Manganese, Iron, and Titanium

- Characteristics:

- Enhanced mechanical properties

- Improved resistance to stress corrosion cracking

- High formability with excellent weldability

- Applications: Cryogenic applications, aerospace shielding, demanding industrial environments

4. Low-Alloy CuNi Foils

- Composition: Copper-rich alloys with <10% Nickel

- Characteristics:

- High thermal and electrical conductivity

- Cost-effective for low-corrosion settings

- Applications: Electronics, EMI/RFI shielding, connectors

5. Custom CuNi Foil Alloys

- Available upon request, DOMADIA™ can manufacture:

- Thin-gauge CuNi foils for microelectronics

- Clad foils combining CuNi with other metals

- Tempered foils for spring or flexible applications

Available Grades

We offer DOMADIA™ Copper Nickel Foils in multiple industry-standard grades:

- CuNi90/10 (UNS C70600 | DIN 2.0872)

- CuNi70/30 (UNS C71500 | DIN 2.0882)

- CuNi30Mn1FeTi (High Performance Alloy)

Each grade offers a unique balance of mechanical strength, corrosion resistance, and thermal stability.

Applications of DOMADIA™ Copper Nickel Foils

DOMADIA™ Copper Nickel Foils offer exceptional resistance to corrosion, stable thermal and electrical properties, and excellent formability. These characteristics make them indispensable across various industries including marine, electronics, aerospace, and more.

🚢 Marine & Offshore Applications

Copper Nickel Foils are widely used in seawater piping, ship hull cladding, and marine heat exchangers. Their natural resistance to saltwater corrosion and biofouling makes them ideal for offshore structures. They also serve as flexible connectors and shielding materials in marine electronics.

⚙️ Heat Exchangers & Thermal Systems

These foils perform reliably in heat exchangers, condensers, and thermal transfer equipment. Their high thermal conductivity, coupled with resistance to corrosion and scaling, ensures efficient operation in harsh environments. Customizable dimensions support both flat and coiled designs.

🔋 Electronics & Battery Technology

In electronics, DOMADIA™ Copper Nickel Foils are used for EMI/RFI shielding, battery terminals, flexible circuits, and bus bars. Their consistent conductivity and low magnetic permeability make them perfect for electric vehicles and portable energy storage systems.

🛰️ Aerospace & Cryogenics

Aerospace and cryogenic systems use these foils for thermal insulation, radiation shielding, and vacuum sealing. Their stability in extreme temperatures and non-magnetic properties ensure precision performance in spacecraft and cryogenic containers.

🎯 Instrumentation & Precision Devices

These foils are ideal for sensors, gauges, and precision instruments that demand dimensional accuracy and corrosion resistance. They are often used in signal cabling, contact surfaces, and protective shielding for electronic measurement devices.

🏭 Industrial & Mechanical Engineering

DOMADIA™ foils are used in diaphragms, bellows, anti-spark gaskets, and seals across chemical and mechanical systems. Their strength, flexibility, and resistance to industrial chemicals make them a durable choice for critical components.

🧩 Custom & Emerging Applications

Beyond traditional uses, these foils are customized for medical devices, hybrid electronics, and decorative metalwork. Their adaptability and high performance support innovation in niche and emerging technological sectors.

Key properties:

1. Corrosion Resistance:

- Copper nickel alloys are highly resistant to seawater corrosion, making them ideal for marine applications like piping, heat exchangers, and condensers.

- The addition of nickel significantly improves the corrosion resistance of copper.

- They can also be used in non-marine applications due to their durability and antibacterial properties.

2. Mechanical Properties:

- Copper nickel alloys offer good strength and durability.

- They can withstand high pressures and temperatures, making them suitable for use in heat exchangers, power generation equipment, and other high-temperature environments.

- The alloy’s ductility allows for easy forming and shaping, which is important for applications like gaskets and seals.

3. Electrical Properties:

- Copper nickel alloys have moderate electrical conductivity.

- This makes them suitable for use in electrical and electronic applications, such as wiring, connectors, and terminals.

- They also have a low temperature coefficient of electrical resistance.

4. Thermal Properties:

- Copper nickel alloys are thermally stable and maintain their mechanical properties at elevated temperatures.

- This makes them suitable for use in applications where they are exposed to high temperatures, such as heat exchangers and power generation equipment.

5. Other Properties:

- Copper nickel alloys are non-magnetic.

- They are easy to work with and can be soldered, brazed, or welded.

- They have good formability and elasticity.

Fabrication & Forming Capabilities

DOMADIA™ Copper Nickel Foils are easy to fabricate using:

- Cold working

- Welding (MIG, TIG, and resistance)

- Brazing & Soldering

- Machining & Etching

Technical Specifications

| Property | Value |

| Density | ~8.9 g/cm³ |

| Melting Point | 1170–1240°C |

| Electrical Resistivity | 0.2–0.3 µΩ·m |

| Tensile Strength | 300–500 MPa |

| Elongation | >30% |

Why Choose DOMADIA™?

At DOMADIA™, we combine metallurgical expertise, precision engineering, and customer-first service to deliver materials that perform under pressure. Whether you’re a procurement head, R&D engineer, or OEM manufacturer — your reliability starts with ours.

Get in touch with us

Looking for copper-nickel foil for your next project? Contact DOMADIA™ for customized dimensions, alloy selection, and volume pricing.

Contact Us Now

📧 Email: sales@domadia.com

📞 Phone: +91-9594066275

Related Products

1. Nickel Foils

2. Titanium Foils

3. Nickel Iron Foils

Error: Contact form not found.