Blogs

The Mystery Metal Behind the Machines: DOMADIA™ Dilaton 46 – UNS K94600

A top-tier electronics manufacturer received a call from an aerospace client — their vacuum diodes kept failing mid-orbit due to unseen micro fractures. The cause? A mismatch in thermal expansion between glass seals and their metal counterparts. The fix? DOMADIA™ Dilaton 46 aka Nickel Iron Glass Sealing Alloy 46, also known as UNS K94600 FeNi46.

This alloy wasn’t just a patch — it was a revolution. Behind that solution was a quietly powerful metal: FeNi46, also known as UNS K94600 / DIN 1.3920.

Let’s break down the science, the specs, and the secrets behind the alloy trusted to hold the future together.

What is DOMADIA™ Dilaton 46 (FeNi46)?

DOMADIA™ Dilaton 46 is a precision-engineered iron-nickel alloy containing approximately 46% nickel, carefully designed for controlled thermal expansion. Its standout feature? A thermal expansion coefficient that matches glass and ceramics, making it essential in electronics and sealing applications.

Chemical Composition:

| Element | Typical Range (%) |

| Iron (Fe) | Balance |

| Nickel (Ni) | ~46.0 |

| Carbon (C) | ≤ 0.05 |

| Manganese (Mn) | ≤ 0.60 |

| Silicon (Si) | ≤ 0.30 |

| Chromium (Cr) | ≤ 0.25 |

| Other Elements | Trace |

Technical Specifications

- UNS K94600 F30

- DIN 1.3920

- Applicable Standards: SEW 385 / DIN 17745 / ASTM F30

- Thermal Expansion (30–300°C): ~6.5 x 10⁻⁶ /°C

- Density: ~8.1 g/cm³

- Curie Temperature: ~230°C

- Electrical Resistivity: ~49 µΩ·cm

- Magnetic Permeability: High

Key Applications

Electronic Glass-to-Metal Sealing

The most critical application: glass sealing in electronic components. FeNi46’s matched thermal expansion ensures crack-free bonds with glass, ideal for:

- Vacuum tubes

- Integrated circuit headers

- X-ray tube components

- hermetic packages including automotive and industrial lamps

Vacuum Sealing Technology

In high-vacuum systems like electron tubes and diodes, DOMADIA™ Dilaton 46 is used for vacuum-tight sealing structures, helping maintain integrity under extreme pressure differentials.

Magnetic Components & Transformers

Its ferromagnetic properties make it perfect for:

- Magnetic recording heads

- Magnetic shielding

- Specialized transformers

Corrosion-Resistant Coatings

When alloyed into intermetallics, DOMADIA™ Dilaton 46 contributes to high-temperature corrosion-resistant coatings — especially for jet engine turbine blades.

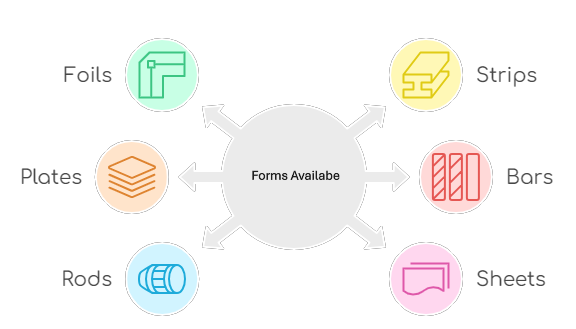

Available Forms

DOMADIA™ Dilaton 46 can be supplied in multiple precise geometries, including:

Standards & Certifications

DOMADIA™ Dilaton 46 complies with industry standards across global markets:

- SEW 385

- DIN 17745

- ASTM F30

This ensures reliability for critical applications where performance can’t be compromised.

Why It Matters — And Where It’s Going

The FeNi46 alloy isn’t flashy — it doesn’t sparkle or shine. But it does something far more important: it expands at just the right rate to protect your technology. From aerospace to quantum electronics, this alloy has earned its place in the hall of engineering fame.

And now, DOMADIA™ Dilaton 46 makes that science accessible, standard-compliant, and form-ready for your exact needs.

Final Thought

If your product depends on precision thermal compatibility, magnetic performance, or vacuum-tight integrity, DOMADIA™ Dilaton 46 might be the most important material you never knew you needed.

Looking for foils? Sheets? Vacuum seal-ready rods?

👉 Contact us now to explore custom solutions for your tech.

Visit our website on https://domadia.net/

Talk to us: Kairav Domadia | Aadil Domadia | Er.Pankaj Domadia | Pragati Sanap | Pooja N N | Shivani Kanojia