Inconel 625 Wire Mesh

High-Strength, Corrosion-Resistant & Engineered for Extreme Environments | Domadia™

Introduction

Inconel 625 Wire Mesh is one of the most reliable high-performance mesh materials used across the most demanding industrial environments. Known for its excellent corrosion resistance, exceptional mechanical strength, and stability in extreme temperatures, this alloy offers unmatched durability for applications where other metals fail. Domadia™ supplies precision-engineered Inconel 625 wire mesh designed to outperform under aggressive chemicals, high heat, seawater, and high-stress conditions.

About Inconel 625 Wire Mesh

Inconel 625 Wire Mesh is manufactured from a premium nickel-chromium-molybdenum-niobium alloy, making it one of the strongest and most corrosion-resistant wire mesh materials available. With operating capability from cryogenic temperatures to 1800°F (982°C), it maintains stability, strength, and non-magnetic properties in all environments.

Its high nickel (min. 58%) and chromium (20–23%) content offer outstanding resistance to pitting, crevice corrosion, stress-corrosion cracking, and oxidizing environments, making it ideal for aerospace, marine, nuclear, and chemical processing applications.

Inconel 625 Wire Mesh – Chemical Composition

| Element | Minimum (%) | Maximum (%) |

| Nickel (Ni) | Balance | – |

| Chromium (Cr) | 20.0 | 23.0 |

| Molybdenum (Mo) | 8.0 | 10.0 |

| Niobium + Tantalum (Nb + Ta) | 3.15 | 4.15 |

| Iron (Fe) | – | 5.0 |

| Manganese (Mn) | – | 0.50 |

| Silicon (Si) | – | 0.50 |

| Carbon (C) | – | 0.10 |

| Phosphorus (P) | – | 0.015 |

| Sulfur (S) | – | 0.015 |

| Aluminum (Al) | – | 0.40 |

| Titanium (Ti) | – | 0.40 |

| Cobalt (Co) | – | 1.0 |

Key Features & Advantages

- Exceptional Corrosion Resistance

Resists acids, alkalis, chlorides, seawater, inorganic & organic chemicals. Excellent against pitting, crevice corrosion, and SCC.

- Outstanding High-Temperature Strength

Performs reliably from cryogenic levels up to 1800°F, maintaining superior toughness and mechanical stability.

- Non-Magnetic in All Conditions

Ensures uniform performance even under severe thermal or mechanical stress.

- Excellent Weldability & Fabrication

Easily welded, cut, shaped, and formed without compromising structural integrity.

- Oxidation & Acid-Resistant

More resistant to oxalic and nitric acids compared to conventional nickel alloys.

- Long Service Life in Harsh Environments

Built to withstand high-pressure, high-stress, and corrosive atmospheres, ensuring maximum durability and reliability.

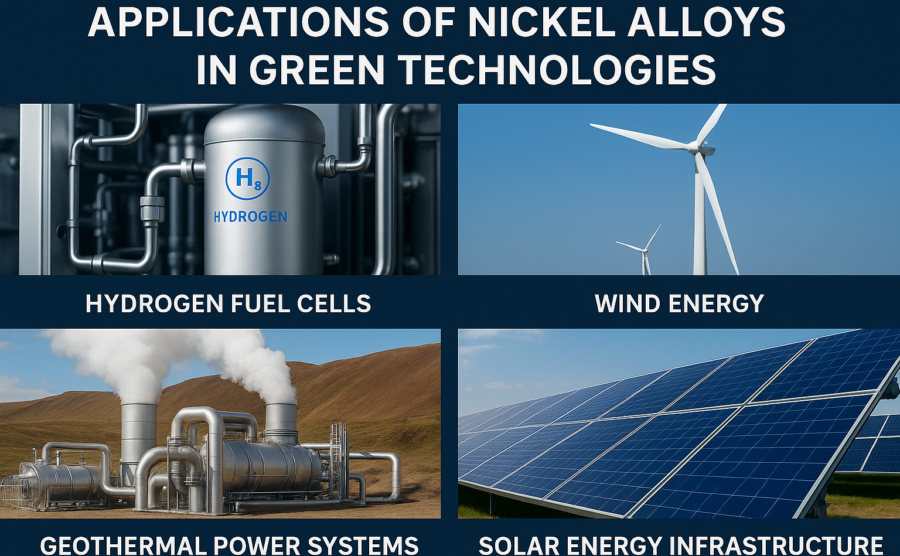

Applications of Inconel 625 Wire Mesh

Each application below is explained in 1–2 lines as requested:

Aerospace & Aviation

Used in jet engines, turbine components, heat shields, and high-temperature filtration due to its extreme heat resistance.

Chemical Processing

Ideal for filters, strainers, and separation screens exposed to aggressive acids, caustics, and corrosive fluids.

Nuclear Industry

Used in nuclear steam generator components for its stability, high strength, and corrosion resistance.

Marine Engineering

Perfect for seawater filters, desalination units, and offshore equipment exposed to chlorides and saltwater corrosion.

Heat Treatment & Furnace Components

Withstands high thermal cycling, making it suitable for furnace baskets, thermal shielding, and high-temperature trays.

Pulp & Paper Industry

Reliable for corrosive bleaching chemicals and high-pressure processing lines.

Flue Gas Desulfurization (FGD)

Performs exceptionally in hot, acidic, and corrosive flue gas environments.

Why Choose Domadia™?

Domadia™ is a trusted global supplier of premium Inconel wire mesh solutions, manufactured with strict quality standards, precise dimensional accuracy, and superior material integrity. Our rigorous testing, international certifications, and advanced production ensure that every mesh performs flawlessly in the world’s harshest conditions. We deliver customizable mesh types, sizes, and packaging designed to meet specific industrial demands with unmatched reliability and consistency.

Connect With Us

At Domadia™, we believe in delivering more than just products—we deliver engineered solutions that elevate your operations. Whether you need corrosion-resistant filtration, high-temperature mesh components, or specialized industrial screening, our experts are ready to assist. We ensure quality assurance at every step, offer global shipping, and provide expert guidance to help you choose the right grade and mesh type for your applications. Connect with our team to discover how Inconel 625 wire mesh can enhance your project performance and longevity.

Ready to Buy ?

Contact Domadia™ Today:

Related Products

- Inconel 600 Wire Mesh

- Hastelloy C276 Wire Mesh

- Monel 400 Wire Mesh

- Titanium Wire Mesh

Frequently Asked Questions (FAQs)

1. What makes Inconel 625 wire mesh resistant to corrosion?

Its high nickel, chromium, and molybdenum content provides strong resistance to pitting, acids, alkalis, and chlorides.

2. Can Inconel 625 withstand seawater?

Yes, it is one of the best alloys for marine applications due to excellent chloride and saltwater corrosion resistance.

3. Is Inconel 625 wire mesh suitable for high-temperature applications?

Absolutely. It maintains exceptional strength up to 1800°F (982°C).

4. What types of wire mesh are available in Inconel 625?

Woven mesh, welded mesh, hexagonal mesh, Dutch weave, fencing mesh, spring steel mesh, and netting mesh.

5. Does Inconel 625 wire mesh support custom sizes?

Yes. Domadia™ offers custom rolls, sheets, panels, and mesh count options as per application needs.

6. Is Inconel 625 magnetic?

No, it remains non-magnetic in all conditions.

7. Does Domadia provide test certificates?

Yes—EN 10204 3.1, radiography reports, PMI tests, mechanical reports, and third-party inspections.

8. What industries most commonly use Inconel 625 wire mesh?

Aerospace, chemical processing, pulp & paper, marine, power generation, and offshore drilling.

Error: Contact form not found.