Mineral Insulated Cables

DOMADIA™ Mineral Insulated (MI) Cables

Precision Engineered for Extreme Environments

At DOMADIA™, we take pride in our world-class manufacturing capabilities for producing Mineral Insulated (MI) cables. Engineered to perform under the most demanding conditions, our MI cables combine the highest-grade materials with advanced manufacturing to deliver unmatched durability, safety, and performance.

These metal-sheathed, fire-resistant cables are designed for extreme industrial environments where traditional cable systems fail. From intense heat to high radiation, DOMADIA™ MI cables provide reliability where it matters most.

Types of MI Cables

1. Mineral Insulated Thermocouple Cable:

Used for temperature measurement, these cables have thermocouple wires insulated with MgO and a metal sheath.

2. Mineral Insulated RTD Cable:

Similar to thermocouple cables, these are used for resistance temperature detection, offering high temperature resistance and durability.

3. Mineral Insulated Heating Cable:

Designed for heating applications, these cables feature a heating element encased in mineral insulation and a metal sheath, suitable for high temperature and high wattage applications.

4. Mineral Insulated Power Cable:

Used for power and control circuits in critical applications, these cables have copper conductors, a solid copper sheath, and MgO insulation for fire safety.

5. Mineral Insulated Coaxial/Triaxial Cable:

These cables are used for data transmission and have a central conductor, a dielectric layer, and a metal sheath.

6. Mineral Insulated Self-Powered Neutron Detectors (SPNDs):

Used in nuclear reactors to measure neutron flux.

7. Flexible Mineral Insulated Cables:

These offer more flexibility, often with a copper or aluminum sheath and MgO insulation, suitable for various industrial applications.

Applications of DOMADIA™ Mineral Insulated Cables

Engineered for Reliability Across Critical Sectors

DOMADIA™ MICC cables are designed to deliver uncompromising performance in the most challenging environments. Their ability to withstand extreme temperatures, resist fire, and maintain structural integrity under pressure makes them a trusted solution across a wide range of industries.

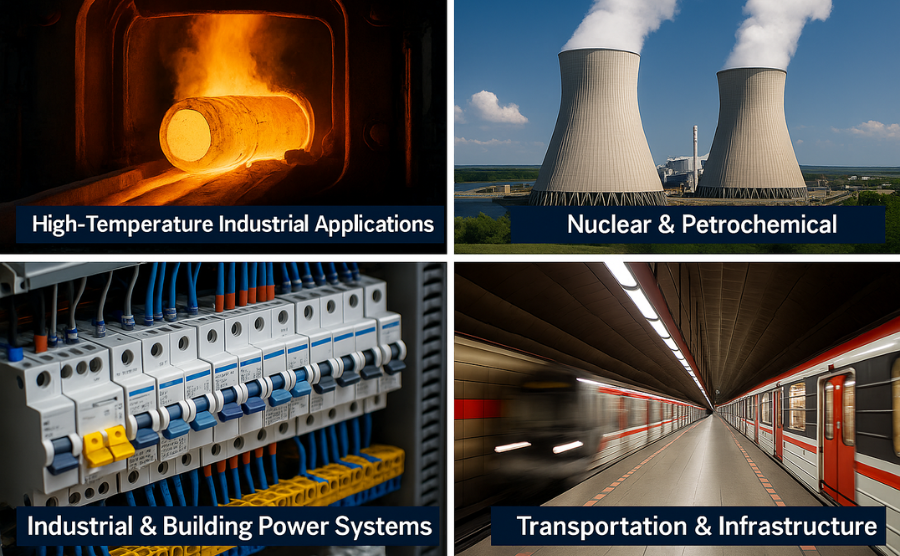

High-Temperature Industrial Applications

DOMADIA™ MICC cables perform reliably in environments above 1000°C. They’re ideal for metal heat-treating, sintering, and ceramic firing.Their strength and thermal stability ensure long-term use in extreme heat.

Nuclear & Petrochemical Industries

Engineered for harsh conditions, these cables resist radiation and chemicals. Used in nuclear reactors and petrochemical plants for safety-critical systems. They offer robust, fail-safe performance in hazardous areas.

Precision Temperature Sensing

Perfect for thermocouples and RTDs in sensitive applications. Used in chemical plants, HVAC systems, and power stations. They provide stable and accurate temperature readings.

Industrial & Building Power Systems

Ideal for critical power in hospitals, data centers, and factories. Strong, maintenance-free, and highly durable over time. Ensure continuous operation in vital systems.

Transportation & Infrastructure

Used in tunnels, metros, airports, and railway networks. Fireproof and low-smoke for safe, enclosed space installations. Withstand vibration, moisture, and heavy-duty use.

Hazardous & Explosive Environments

Safe for areas with flammable gases or corrosive chemicals. Used in chemical plants, oil refineries, and offshore sites. Metal sheathing ensures unmatched protection and reliability.

Fire protection systems

Fire alarm systems: Ensuring alarm systems remain operational during a fire. This includes fire alarm systems in high-rise buildings.

Emergency lighting: Maintaining power to emergency lighting circuits to guide occupants safely during emergencies and ensure the lighting is functional during the fire.

Sprinkler systems: Powering the control systems of fire suppression sprinklers.

Hazardous locations

Chemical and petrochemical plants: Operating in corrosive environments with explosive atmospheres and high-temperature environments like furnaces and kilns.

Oil and gas industry: Used in offshore rigs and refineries where high reliability and safety standards are required. Used in environments where explosive gases, dust, or vapours are present, ensuring safe and reliable electrical connections.

Building and construction

Critical infrastructure: Wiring in hospitals, airports, tunnels, and other critical infrastructure.

Historical buildings: Retrofitting old buildings with fire-resistant wiring without compromising architectural integrity.

Transportation

Railways and subways: Providing reliable power and control wiring in underground and elevated transit systems, as well as lighting systems.

Marine applications: Used in ships and offshore platforms where exposure to harsh marine environments and corrosion is common. It is also used to connect warning systems at sea and on oil tankers in extreme conditions.

Specialized equipment

Medical devices: Ensuring the reliability of sensitive medical equipment and systems.

Instrumentation and control: In precision instruments that require stable and reliable electrical connections.

Renewable energy

Solar power plants: Used in solar power installations where reliability and longevity are crucial.

Wind turbines: Providing power and control wiring for wind turbines in harsh and varying weather conditions.

Data centers

Ensuring the integrity and reliability of uninterrupted power supply to critical data centre infrastructure, minimizing the risk of downtime due to fire or other hazards.

Military and defence

Weapon systems: Used in critical defence systems where high reliability under extreme conditions is required.

Field operations: Providing robust and reliable power in field-deployed equipment and temporary installations.

Key Features of Mineral Insulated (MI) Cables

Built for Safety, Performance, and Longevity. Mineral Insulated (MI) Cables are the benchmark for high-performance wiring in critical and demanding environments. Engineered to deliver unrivaled reliability, MI cables offer a combination of mechanical strength, thermal endurance, and fire resistance that conventional cables cannot match. Here’s what sets them apart:

1. Exceptional Fire Resistance

MI cables are completely fireproof. Thanks to their inorganic construction using metal sheathing and compressed magnesium oxide insulation, they can withstand direct exposure to flame and continue operating during and after a fire event — ensuring life-saving systems like alarms and emergency lighting stay functional when needed most.

2. High Temperature Endurance

Designed for the extremes, MI cables can operate safely in environments with temperatures exceeding 1000°C. Whether it’s in industrial kilns, heat-treating furnaces, or nuclear plants, they maintain stability and insulation integrity without deterioration.

3. Superior Mechanical Strength

With a rugged metal sheath and compact design, MI cables are highly resistant to mechanical damage. They can endure vibration, compression, and crushing — making them perfect for underground, marine, and transportation-related installations.

4. Zero Maintenance, Long Lifespan

Once installed, MI cables require no ongoing maintenance. Their corrosion resistance, thermal stability, and robust insulation ensure decades of dependable performance with minimal risk of failure or degradation.

5. Radiation and Chemical Resistance

MI cables are ideal for harsh environments such as nuclear reactors, petrochemical facilities, and offshore platforms. They resist radiation, oil, acids, and most industrial chemicals — providing safe and stable operation in hazardous conditions.

6. High Insulation Resistance

The use of compressed mineral insulation (magnesium oxide) offers extremely high insulation resistance. This makes the cable immune to moisture, which is a common cause of failure in conventional cables.

7. Low Smoke, Zero Toxicity

In the event of a fire, MI cables do not emit smoke, toxic fumes, or gases. This is especially important for installations in enclosed or populated areas such as tunnels, hospitals, aircraft, and public buildings.

8. Flexible Design and Customization

Available in a variety of configurations — from single-core to multi-core, and in different sheath materials like copper, stainless steel, or Inconel — MI cables can be tailor-made to suit virtually any application or regulatory requirement.

Unique construction provides several advantages:

1. High temperature resistance:

Mineral insulated (MI) cables can typically handle a wide range of temperatures, with some designs offering minimum operating temperatures as low as -80°C (-112°F) and maximum operating temperatures of 1200°C (2192°F). MI cables can withstand high temperatures up to 1083°C, the melting point of the copper conductor. The magnesium oxide (MgO) powder insulation can actually withstand temperatures up to 2800°C.

2. Fire resistance:

The non-combustible materials used in MI cables ensure they maintain functionality even during a fire, making them ideal for critical circuits in buildings. The cable is fire-resistant in temperatures of 950 °C for 180 minutes.

3. Moisture resistance:

The solid copper sheath protects against moisture ingress, making these cables suitable for wet or corrosive environments.

4. Durability:

MI cables are highly resistant to physical damage due to their robust construction.

5. Compact size:

The lack of organic insulation materials allows MI cables to have a smaller diameter than other cables with the same current-carrying capacity. The cable has a higher carrying capacity than other cables of this size.

MI cable is also smoke-free, halogen-free, and resistant to radiation.

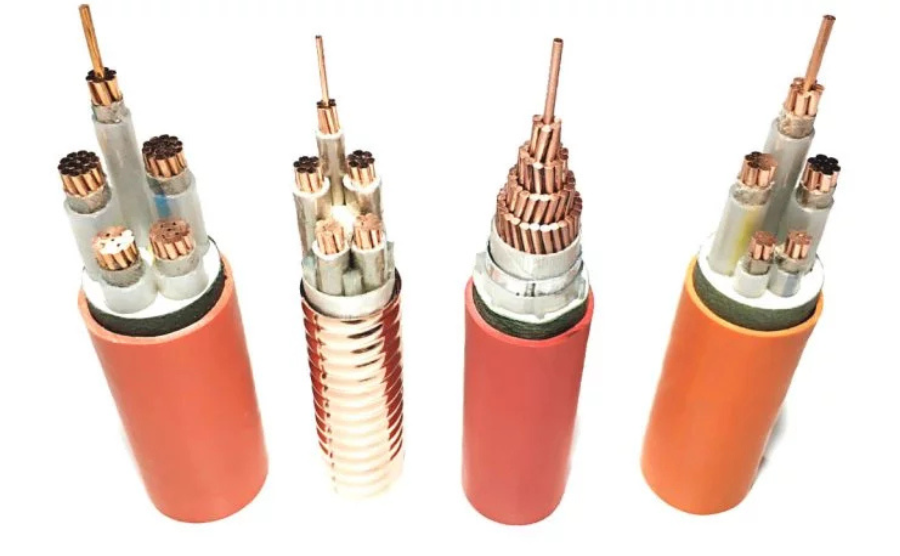

MI cable construction

The construction of Mineral Insulated (MI) cable is unique and consists of the following components (inorganic compounds):

1. Conductor:

Material: Copper (or sometimes other metals like stainless steel for specific applications).

Number of conductors: Typically single or multiple solid conductors.

2. Insulation:

Material: Magnesium Oxide (MgO) powder.

Properties: MgO is an inorganic material that provides excellent electrical insulation and high-temperature resistance.

3. Sheath:

Material: Copper (most common) or sometimes stainless steel for additional corrosion resistance.

Purpose: The sheath provides mechanical protection and acts as an electrical shield. For environments requiring additional protection against corrosion, stainless steel or other materials can be used for the sheath.

Where is MI cable prohibited?

While not directly prohibited, MI cables are not suitable for:

- Flexible, temporary, and moving installations. MI cables are rigid and difficult to install in flexible environments.

- General residential use: While MI cables are excellent for specific critical applications, they are typically not used for general residential wiring due to cost, installation complexity, and other suitable alternatives.

DOMADIA™ MI Enhanced Grade Wiring Cable System

The DOMADIA™ MI Cable range offers an optimal solution for a wide variety of low voltage electrical circuits. Available in two voltage ratings—500 and 750 Volts—this range features conductors ranging from 1.0 sq.mm to 240 sq.mm. Additionally, a comprehensive selection of complementary accessories and tools ensures a complete wiring system, all backed by the assurance of “Genuine DOMADIA™ ” components.

DOMADIA™ MI Cables Benefits

- DOMADIA™ MI survives the fire test requirements for enhanced grade cables as defined in BS 5839: part 1.

- Peace of mind from the third party (LPCB) approval for categories C, W and Z in BS 6387.

- Also attains categories C, W and Z of BS 6387 with one single cable sample.

DOMADIA™ MI Cables Construction

With a basic inorganic construction of a copper sheath and conductors, together with a mineral insulant, the cable provides a unique combination of dependability, versatility and permanence.

This construction, with the melting points of 1083°C and 2800°C for the copper and the insulant respectively, provides the unsurpassed Fire Survival properties which enable the cable to continue to carry current at temperatures in excess of 1000°C.

DOMADIA™ MI Construction Characteristics

- Fireproof

- High Operating Temperatures

- Inherent Flameproof Barrier

- Zero Energy

- Non-Ageing

- Great Mechanical Strength

- Small Overall Diameter

- Pliable

- Wiring Cable and Conduit Combined

- Competitive Installed Cost

- High Degree of Electrical Screening

- Radiation Resistant

- Integral Earth Continuity

- High Corrosion Resistance

- Waterproof

DOMADIA™ Twist Cable System

DOMADIA™ Twist is a range of communication and signal cables for life preservation and integrated building management systems.

They have been developed from the proven characteristics of DOMADIA™ MI to maintain the security of vital signals in communication and data networks, particularly in hostile conditions.

DOMADIA™ Twist MI Cables Additional Characteristics and Advantages

- Twisted conductor configuration with a solid copper screen.

- DOMADIA™ Twist available in red (other colours available upon request).

- DOMADIA™ Twist uses standard accessories for the equivalent DOMADIA™ MI Light Duty cable size.

- DOMADIA™ Twist can be installed and terminated by following the normal procedures for DOMADIA™ MI Cable.

- The twisted copper conductor configuration enhances the EMC noise rejection characteristics, reducing the possibility of system malfunction.

- The exceptionally low impedance of the solid copper sheath provides a superior EMC screening than other cable systems.

- Minimal smoke obscuration in the event of fire.

Frequently Asked Questions (FAQs)

1. What are Mineral Insulated Cables (MICC)?

Mineral Insulated Cables are made of copper or alloy conductors, compressed magnesium oxide insulation, and a metal sheath. They are known for their exceptional fire resistance, high-temperature endurance, and mechanical strength.

2. Where are MICC cables commonly used?

MICC cables are widely used in fire protection systems, nuclear facilities, petrochemical plants, industrial furnaces, and temperature sensing devices like thermocouples and RTDs. They’re also common in hospitals, tunnels, and data centers.

3. Can MICC cables withstand high temperatures?

Yes, MICC cables can operate in environments exceeding 1000°C. Their construction makes them ideal for extreme heat conditions like metal processing and kiln operations.

4. Are MICC cables fireproof?

Absolutely. MICC cables are inherently fire-resistant and maintain circuit integrity even during and after a fire. They are ideal for life safety systems and emergency circuits.

5. Are MICC cables suitable for hazardous or explosive environments?

Yes, the metal sheath and inorganic insulation make MICC cables safe for use in areas with flammable gases, corrosive chemicals, or explosive dust — such as in petrochemical plants and offshore platforms.

6. Can MICC cables be customized for specific applications?

Yes. At DOMADIA™, we offer custom-built MICC cables based on your application’s temperature range, conductor type, sheath material, and insulation requirements.

7. Do MICC cables require regular maintenance?

No. One of the key advantages of MICC cables is their zero-maintenance nature. Once installed, they offer long service life without the need for upkeep.

8. What sheath materials are available for MICC cables?

Common sheath options include copper, stainless steel, and Inconel, each chosen based on corrosion resistance, temperature handling, and environmental exposure.

9. What standards do DOMADIA™ MICC cables comply with?

DOMADIA™ MICC cables are manufactured to meet international quality and safety standards, ensuring compliance with industry-specific requirements in nuclear, industrial, and infrastructure sectors.

Related Products

1. Copper Conductor Cables

2. Nickel Conductor Cables

3. Beryllium Copper Conductor Cables

Error: Contact form not found.