TITANIUM & ALLOYS

TITANIUM & ALLOYS

Titanium & Alloys Manufacturer In India (DALI ELECTRONICS / VIJAY COMMERCIAL HOUSE) Provides Quality Products, at Competitive prices, with the quickest deliveries. We offer the largest selection of Titanium Wire, Bar, Plate, Sheet, Pipe, Tube and more as well as the most value-added services in the Industry for all end-use Markets.

At Titanium India, We offer NABL Lab Certified Best Quality Products. Because of the pivotal role we play in your Business, Titanium India is committed to creating and maintaining strong relationships with our customers, built on a Foundation of Excellence and Trust. From the products We supply to our Dedicated Customer Service, We know what’s important to you.

We are always there for you.

WHAT IS TITANIUM

Titanium is a lustrous, white metal when pure. Titanium minerals are quite common. The metal has a low density, good strength, is easily fabricated, and has excellent corrosion resistance. The metal burns in air and is the only element that burns in nitrogen. It is marvelous in fireworks.

Titanium is resistant to dilute sulphuric and hydrochloric acid, most organic acids, damp chlorine gas, and chloride solutions.

| TITLE | DESCRIPTION |

|---|---|

| Name | Titanium |

| Symbol Atomic number | 22 |

| Relative atomic mass (Ar) | 47.867 (1) |

| Standard state | Solid at 298 K |

| Colour | Silvery metallic |

| Classification | Metallic |

| Group in periodic table | 4 |

| Group name | None |

| Period in periodic table | 4 |

| Block in periodic table | d-block |

| Electron shell structure | 2.8.10.2 CAS |

| Registry ID | 7440-32-6 |

WHAT ARE THE TITANIUM APPLICATION & USES

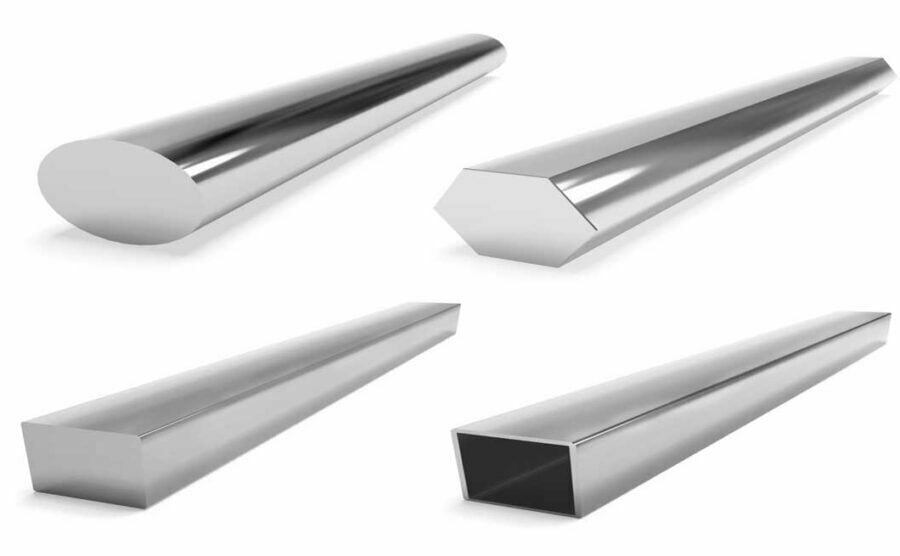

Titanium is used in Steel as an alloying element (ferrotitanium) to reduce grain size and as a deoxidizer and in stainless steel to reduce carbon content. Titanium is often alloyed with aluminium (to refine grain size), vanadium, copper (to harden), iron, manganese, molybdenum, and other metals. Applications for Titanium mill products (sheet, plate, bar, wire, forgings, and castings) can be found in Industrial, Aerospace, Recreational, and Emerging markets. Powdered Titanium is used in Pyrotechnics as a source of bright-burning particles.

PIGMENTS, ADDITIVES, AND COATINGS

- Watch glass on a black surface with a small portion of white powder.

- Titanium dioxide is the most commonly used compound of titanium.

About 95% of Titanium ore extracted from the Earth is destined for refinement into Titanium Dioxide (TiO2), an intensely white permanent pigment used in paints, paper, toothpaste, and plastics. It is also used in cement, in gemstones, as an optical opacifier in paper, and a strengthening agent in graphite composite fishing rods and golf clubs.

TiO2 powder is chemically inert, It resists fading in sunlight and is very opaque. This allows it to impart a pure and brilliant white color to the brown or gray chemicals that form the majority of Household Plastics. In nature, this compound is found in the minerals anatase, brookite, and rutile. Paint made with Titanium dioxide does well in severe temperatures and stands up to marine environments. Pure titanium dioxide has a very high index of refraction and an optical dispersion higher than diamond. In addition to being a very important pigment, Titanium dioxide is also used in sunscreens.

AEROSPACE AND MARINE

Due to their high tensile strength to density ratio, high corrosion resistance, fatigue resistance, high crack resistance, and ability to withstand moderately high temperatures without creeping, Titanium Alloys are used in Aircraft, Armor Plating, Naval Ships, Spacecraft, and Missiles. For these applications titanium alloyed with aluminium, zirconium, nickel, vanadium, and other elements is used for a variety of components including critical structural parts, firewalls, landing gear, exhaust ducts (helicopters), and hydraulic systems. About two third of all titanium metal produced is used in Aircraft Engines and Frames.

Due to its high corrosion resistance to seawater, It is used to make propeller shafts and rigging and in the heat exchangers of desalination plants; in heater-chillers for saltwater aquariums, fishing line, and leader, and divers’ knives. Titanium is used to manufacture the housings and other components of ocean-deployed surveillance and monitoring devices for scientific and military use. The Former Soviet Union developed techniques for making submarines with hulls of titanium alloys. Techniques were developed in the Soviet Union to forge Titanium in Huge Vacuum Tubes.

INDUSTRIAL

Welded Titanium pipe and process equipment (heat exchangers, tanks, process vessels, valves) are used in the chemical and petrochemical industries primarily for corrosion resistance. Specific alloys are used in downhole and nickel hydrometallurgy applications due to their high strength (e. g.: titanium Beta C alloy), corrosion resistance or a combination of both. The pulp and paper industry uses titanium in process equipment exposed to corrosive media such as sodium hypochlorite or wet chlorine gas (in the bleachery). Other applications include Ultrasonic Welding, Wave Soldering and sputtering targets.

(TiCl4) Titanium Tetrachloride, a Colorless Liquid, is Important as an intermediate in the process of making TiO2 and is also used to produce the Ziegler–Natta catalyst. Titanium tetrachloride is also used to iridize glass and, because it fumes strongly in moist air, it is used to make smoke screens.

CONSUMER AND ARCHITECTURAL

Titanium metal is used in Automotive Applications, particularly in automobile or motorcycle racing, where weight reduction is critical while maintaining high strength and rigidity. The metal is generally too expensive to make it marketable to the general consumer market, other than high-end products, particularly for the racing/performance market. Some late model Corvettes have been available with titanium exhausts, and the new Corvette Z06’s LT4 supercharged engine uses lightweight, solid titanium intake valves for greater strength and resistance to heat.

Titanium is used in many sporting goods: Tennis Rackets, Golf clubs, Lacrosse stick shafts; Cricket, Hockey, Lacrosse, and Football Helmet Grills; and Bicycle frames and components. Although not a mainstream material for bicycle production, Titanium bikes have been used by race teams and adventure cyclists. Titanium alloys are also used in spectacle frames. This results in a rather expensive, but highly durable and long-lasting frame which is light in weight and causes no skin allergies. Many backpackers use titanium equipment, including cookware, eating utensils, lanterns, and tent stakes. Though slightly more expensive than traditional steel or aluminium alternatives, these titanium products can be significantly lighter without compromising strength. It is also favored for use by farriers because it is lighter and more durable than steel when formed into horseshoes.

Because of its superior strength and lightweight when compared to other metals traditionally used in firearms (steel, stainless steel, and aluminium), and advances in metalworking techniques, Using Of Titanium has been Widely Spread in the Manufacturing of Firearms. Primary uses include pistol frames and revolver cylinders. For these same reasons, it is also used in the body of Laptop Computers.

Some upmarket categories of tools made to be lightweight and corrosion-resistant, such as shovels and flashlights, are made of titanium or titanium alloys as well.

JEWELLERY

Because of its durability, titanium has become more popular for designer jewelry (particularly, titanium rings). Its inertness makes it a good choice for those with allergies or those who will be wearing the jewelry in environments such as swimming pools. Titanium is also alloyed with gold to produce an alloy that can be marketed as 24-carat gold, as the 1% of alloyed Ti is insufficient to require a lesser mark. The resulting alloy is roughly the hardness of 14-carat gold and thus is more durable than a pure 24-carat gold item would be.

Titanium’s durability, lightweight, dent- and corrosion resistance makes it useful in the production of watch cases. Some artists work with titanium to produce artworks such as sculptures, decorative objects, and furniture.

The inertness and ability to be attractively colored makes titanium a popular metal for use in body piercing. Titanium may be anodized to produce various colors, which varies the thickness of the surface oxide layer and causes interference fringes.

MEDICAL

Titanium biocompatibility: Because it is biocompatible (it is non-toxic and is not rejected by the body), titanium has many medical uses, including surgical implements and implants, such as hip balls and sockets (joint replacement) that can stay in place for up to 20 years. The titanium is often alloyed with about 4% aluminium or 6% Al and 4% vanadium.

Titanium has the inherent ability to osseointegrate, enabling use in dental implants that can last for over 30 years. This property is also useful for orthopedic implant applications. These benefit from titanium’s lower modulus of elasticity (Young’s modulus) to more closely match that of the bone that such devices are intended to repair. As a result, skeletal loads are more evenly shared between bone and implant, leading to a lower incidence of bone degradation due to stress shielding and periprosthetic bone fractures, which occur at the boundaries of orthopedic implants. However, titanium alloys’ stiffness is still more than twice that of bone, so adjacent bone bears a greatly reduced load and may deteriorate.

Because titanium is non-ferromagnetic, patients with titanium implants can be safely examined with magnetic resonance imaging (convenient for long-term implants). Preparing titanium for implantation in the body involves subjecting it to a high-temperature plasma arc which removes the surface atoms, exposing fresh titanium that is instantly oxidized.

Titanium is also used for the surgical instruments used in image-guided surgery, as well as wheelchairs, crutches, and any other products where high strength and low weight are desirable.

NUCLEAR WASTE STORAGE

Due to its extreme Corrosion Resistance, Titanium containers have been studied for the long-term storage of nuclear waste (containers lasting over 100,000 years are possible under proper manufacturing conditions to reduce defects in the process). A titanium “drip shield” could also be placed over other types of containers to further contain the waste.

TITANIUM GRADES / ALLOYS

There are several grades available… but ready and commonly available with us is Grade II & Grade V. Other Grades can be made available for large quantities.

- Grade 1 is the most ductile and softest titanium alloy. It is a good solution for cold forming and corrosive environments.ASTM/ ASME SB-265 provides the standards for commercially pure titanium sheet and plate.

- Grade 2:- Unalloyed titanium, standard oxygen.

- Grade2H:- Unalloyed titanium (Grade 2 with 58 KSI minimum UTS).

- Grade3:- Unalloyed titanium, medium oxygen.

- Grades 1-4 are unalloyed and considered commercially pure or “CP”. Generally, the tensile and yield strength goes up with grade numbers for these “pure” grades. The difference in their physical properties is primarily due to the quantity of interstitial elements. They are used for corrosion resistance applications where cost, ease of fabrication, and welding are important.

- Grade 5 also known as Ti6Al4V, Ti-6Al-4V or Ti 6-4, is the most commonly used alloy. It has a chemical composition of 6% aluminum, 4% vanadium, 0.25% (maximum) iron, 0.2% (maximum) oxygen, and the remainder titanium. It is significantly stronger than commercially pure titanium while having the same stiffness and thermal properties (excluding thermal conductivity, which is about 60% lower in Grade 5 Ti than in CP Ti). Among its many advantages, it is heat treatable. This grade is an excellent combination of strength, corrosion resistance, weld, and fabricability. This alpha-beta alloy is the workhorse alloy of the titanium industry. The alloy is fully heat treatable in section sizes up to 15 mm and is used up to approximately 400 °C (750 °F). Since it is the most commonly used alloy – over 70% of all alloy grades melted are a sub-grade of Ti6Al4V, its uses span many aerospace airframes and engine component uses and also major non-aerospace applications in the marine, offshore and power generation industries in particular. Applications: Blades, discs, rings, airframes, fasteners, components. Vessels, cases, hubs, forgings. Biomedical implants. Generally, Ti-6Al-4V is used in applications up to 400 degrees Celsius. It has a density of roughly 4420 kg/m3, Young’s modulus of 115 GPa, and tensile strength of 1000 MPa. By comparison, annealed type 316 stainless steel has a density of 8000 kg/m3, modulus of 193 GPa, and tensile strength of 570 MPa. Tempered 6061 aluminium alloy has a density of 2700 kg/m3, modulus of 69 GPa, and tensile strength of 310 MPa, respectively.

- Grade 6:- Contains 5% aluminium and 2.5% tin. It is also known as Ti-5Al-2.5Sn. This alloy is used in airframes and jet engines due to its good weldability, stability, and strength at elevated temperatures.

- Grade 7:- Contains 0.12 to 0.25% palladium. This grade is similar to Grade 2. The small quantity of palladium added gives it enhanced crevice corrosion resistance at low temperatures and high pH.

- Grade 7H:- It is identical to Grade 7 with enhanced corrosion resistance.

- Grade 9:- Contains 3.0% aluminium and 2.5% vanadium. This grade is a compromise between the ease of welding and manufacturing of the “pure” grades and the high strength of Grade 5. It is commonly used in aircraft tubing for hydraulics and athletic equipment.

- Grade 11:- Contains 0.12 to 0.25% palladium. This grade has enhanced corrosion resistance.

- Grade 12:- Contains 0.3% molybdenum and 0.8% nickel.

- Grades 13, 14, and 15:- All Contain 0.5% nickel and 0.05% ruthenium.

- Grade 16:- Contains 0.04 to 0.08% palladium. This grade has enhanced corrosion resistance.

- Grade 16H:- Contains 0.04 to 0.08% palladium.

- Grade 17:- Contains 0.04 to 0.08% palladium. This grade has enhanced corrosion resistance.

- Grade 18:- Contains 3% aluminium, 2.5% vanadium and 0.04 to 0.08% palladium. This grade is identical to Grade 9 in terms of mechanical characteristics.

The added palladium gives it increased corrosion resistance.

- Grade 19:- Contains 3% aluminium, 8% vanadium, 6% chromium, 4% zirconium, and 4% molybdenum.

- Grade 20:- Contains 3% aluminium, 8% vanadium, 6% chromium, 4% zirconium, 4% molybdenum and 0.04% to 0.08% palladium.

- Grade 21:- Contains 15% molybdenum, 3% aluminium, 2.7% niobium, and 0.25% silicon.

- Grade 23:- Contains 6% aluminium, 4% vanadium, 0.13% (maximum) Oxygen. Improved ductility and fracture toughness with some reduction in strength.

- Grade 24:- Contains 6% aluminium, 4% vanadium and 0.04% to 0.08% palladium.

- Grade 25:- Contains 6% aluminium, 4% vanadium and 0.3% to 0.8% nickel and 0.04% to 0.08% palladium.

- Grades 26, 26H, and 27:- All Contain 0.08 to 0.14% ruthenium.

- Grade 28:- Contains 3% aluminium, 2.5% vanadium and 0.08 to 0.14% ruthenium.

- Grade 29:- Contains 6% aluminium, 4% vanadium and 0.08 to 0.14% ruthenium.

- Grades 30 and 31:- Contain 0.3% cobalt and 0.05% palladium.

- Grade 32:- Contains 5% aluminium, 1% tin, 1% zirconium, 1% vanadium, and 0.8% molybdenum.

- Grades 33 and 34:- Contain 0.4% nickel, 0.015% palladium, 0.025% ruthenium, and 0.15% chromium .

- Grade 35:- Contains 4.5% aluminium, 2% molybdenum, 1.6% vanadium, 0.5% iron, and 0.3% silicon.

- Grade 36:- Contains 45% niobium.

- Grade 37:- Contains 1.5% aluminium.

- Grade 38:- Contains 4% aluminium, 2.5% vanadium, and 1.5% iron. This grade was developed in the 1990s for use as an armor plating. The iron reduces the amount of Vanadium needed as a beta stabilizer. Its mechanical properties are very similar to Grade 5 but have good cold workability similar to grade 9.

For Any Inquiries Contact:-

(Metal Division)

Call +91 8928403617 or Email: titanium@domadia.com

Error: Contact form not found.