Blogs

The Smart Alloy for Thermal Sealing – DOMADIA™ Dilaton 48Cr6Al (UNS N14052)

A Metal with a Secret Mission: Thermal Precision at Its Core

Imagine designing an electronic component that never shifts, swells, or shrinks—no matter how wildly the temperature dances. Now, what if there was a metal engineered to keep that promise?

Meet DOMADIA™ Dilaton 48Cr6Al (UNS N14052) – a premium Fe-Ni-Cr-Al alloy, developed for mission-critical environments where dimensional stability, thermal sealing, and magnetic control are non-negotiable. This alloy doesn’t just play by the rules—it redefines them.

Explanation & Innovation

DOMADIA™ Dilaton 48Cr6Al is a high-performance iron-nickel-based alloy enhanced with chromium and aluminum. It belongs to the family of low expansion alloys, offering near-zero dimensional changes across temperature fluctuations. Its unique formulation minimizes oxidation, maximizes magnetic stability, and enables perfect glass-to-metal sealing—even in aggressive environments.

Whether it’s in vacuum tubes, hybrid circuits, or aerospace-grade sensors, this alloy brings unmatched reliability.

The chemical composition of DOMADIA™ Dilaton 48Cr6Al (UNS N14052)

| Element | Content (%) |

| Iron (Fe) | Balance |

| Nickel (Ni) | ~48.0 |

| Chromium (Cr) | ~6.0 |

| Aluminum (Al) | Trace to 1.0 |

| Manganese (Mn), Silicon (Si), Carbon (C) | Residuals |

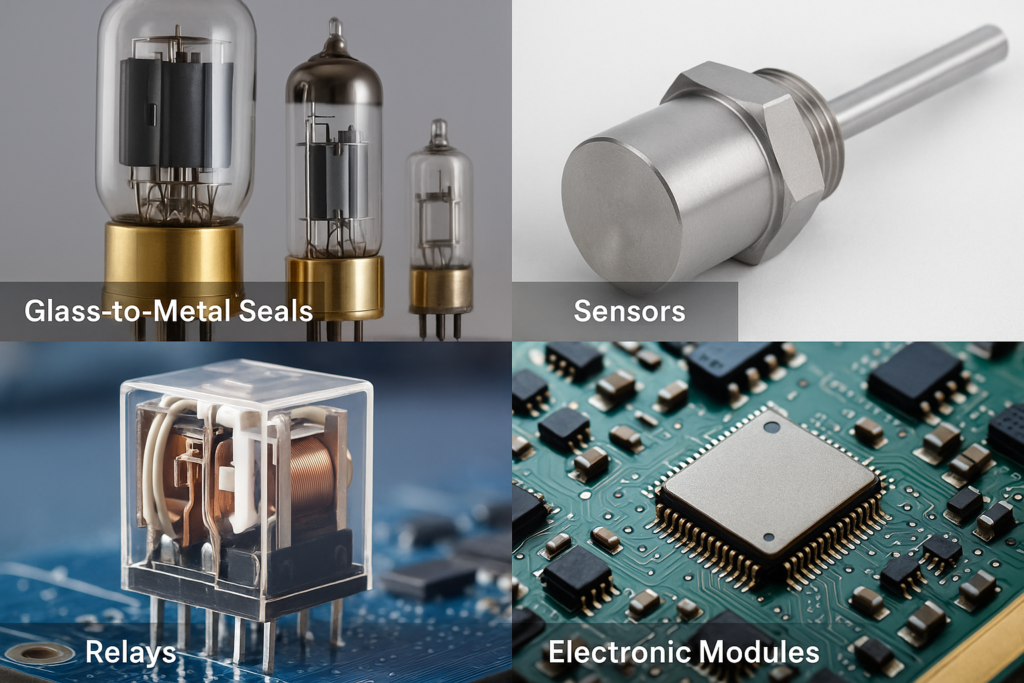

Applications of DOMADIA™ Dilaton 48Cr6Al

This alloy is a superstar in industries where thermal matching and hermetic sealing are vital. Key applications include:

Glass-to-Metal Seals

Alloy 52 is widely used in the manufacturing of electronic packages, vacuum tubes, and hermetic seals for sensitive components. Its compatibility with soft glasses and ceramics allows for reliable glass-to-metal sealing, ensuring long-term durability and performance.

Electronics

In the electronics industry, Alloy 52 is used in components like lead frames and connectors, where its stable thermal expansion and electrical properties ensure reliable connections and packaging.

Precision Engineering

The alloy’s ability to maintain dimensional stability across a range of temperatures makes it ideal for precision engineering applications. Components made from Alloy 52 exhibit consistent performance even under varying thermal conditions.

Magnetic Devices

Alloy 52’s controlled expansion and magnetic properties are beneficial in certain sensor and actuator designs, enhancing the reliability and accuracy of these devices.

Other Industrial Applications

Beyond the specific applications mentioned, Alloy 52 is also used in a variety of other industrial contexts. Its corrosion resistance makes it suitable for environments where exposure to atmospheric conditions and certain chemicals is a concern. The alloy’s combination of mechanical strength, thermal stability, and resistance to wear and tear ensures its effectiveness in a wide range of high-tech and industrial applications, including aerospace components and specialized machinery parts.

Standards & Designations

- UNS Number: N14052

- DIN: 17745

- SEW: 385

- Alloy Name: FeNi48Cr6Al

DOMADIA™ Dilaton 48Cr6Al is precision-made to conform to global engineering benchmarks.

Key Properties of DOMADIA™ Dilaton 48Cr6Al

Physical Properties

- Density: 8.3 g/cm³ (0.30 lb/in³)

- Melting Range: 1427–1430°C (2600°F)

- Curie Temperature: ~530°C (986°F)

- Electrical Resistivity: 43 microhm-cm at 20°C (68°F)

- Thermal Conductivity: 140 W/m·K (18 W/cm·°C)

- Specific Heat: 0.12 cal/g·°C

- Mean Coefficient of Thermal Expansion (25–450°C): 9.8 µm/m·°C (5.4 µin/in·°F)

- Thermal Expansion Stability: Nearly constant up to ~565°C (1050°F)

Mechanical Properties

- Ultimate Tensile Strength: 75–78 ksi (517–536 MPa)

- Yield Strength: 35–40 ksi (240–276 MPa)

- Elongation: 30–35% (in 2 in.)

- Hardness: Rb 73 (nominal)

Technical Specifications

- Melting Range: Approx. 1400–1450°C

- Annealing Temperature: 800–1000°C (in H₂ or vacuum atmosphere)

- Thermal Conductivity: ~11 W/m·K

- Modulus of Elasticity: ~140 GPa

- Cold Forming Capability: Excellent

- Surface Finish Available: Bright, matte, ground

DOMADIA™ offers customized finishing for application-specific needs such as laser welding, sputtering, and photoetching.

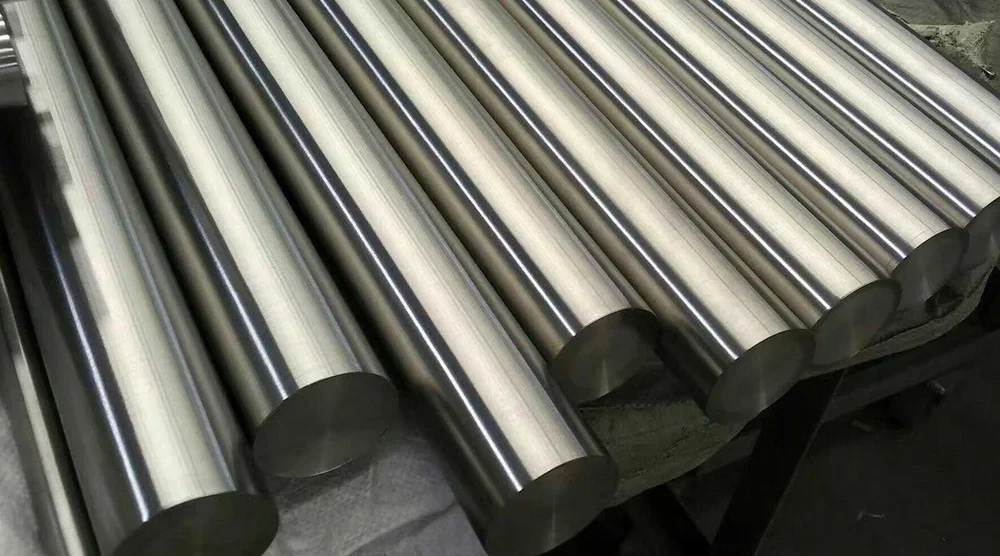

Available Forms / Shapes

DOMADIA™ Dilaton 48Cr6Al can be supplied in a variety of precision-engineered forms:

- Foils

- Strips

- Plates

- Bars

- Rods

- Sheets

These forms are offered in tight tolerance dimensions, ready for integration into electronic, vacuum, and magnetic systems.

Conclusion: A Future-Proof Metal for High-Stakes Engineering

In a world where devices are getting smarter and components are shrinking, materials like DOMADIA™ Dilaton 48Cr6Al become essential. Its low expansion, high sealing ability, and magnetic performance make it the go-to alloy for next-gen thermal and electronic challenges.

Whether you are sealing, shielding, or stabilizing—Dilaton 48Cr6Al gets the job done.

📩 Contact us today or visit https://domadia.net/ to explore DOMADIA™ Dilaton 48Cr6Al.

Need help choosing the right form factor? Contact our experts today!

Talk to: Kairav Domadia | Aadil Domadia | Er.Pankaj Domadia | Pragati Sanap | Pooja N N | Shivani Kanojia